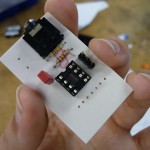

OK time to put some components onto my board to see if I’ve got this right so far. The soldering was quite easy, some of my GCSE knowledge came drifting back up from where it was buried in my brain plus a couple of the guy’s here have worked as electrical engineers (thanks Steve!) Tips: […]